Differentials and driveshafts

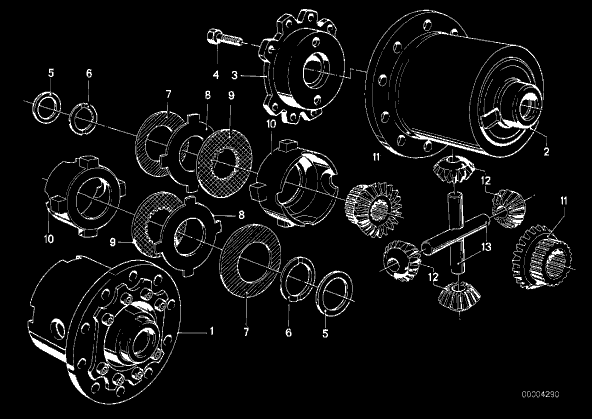

Differentials are fully disassembled and then casing and all parts thoroughly cleaned. The cover is then vapour blasted. The case is then painted with epoxy primer and a high temperature polyurethane topcoat. All bearings, sleeves and seals are replaced - with OE brands. If a limited slip differential, the clutch plates are inspected for wear and replaced where appropriate. New bushings can be pressed into the differential cover. All fasteners and dust caps are zinc plated to match factory finish. Upon reassembly, the greatest of care is used to ensure the differential meets specification. This includes accurately measuring backlash and preload using specialist tools.

Driveshafts are disassembled and thoroughly cleaned to remove any old grease from the CV joints. The housings, cages and ball bearings are all organised so they go exactly in the position they were when its time to reassemble. The shafts are then sandblasted and finished in a coating of your choice. New dust boots, dust caps and clips are sourced and fresh grease applied into each CV joint.